Let me tell you the secret to sharpening anything.

YOU PUT A BURR ON THE BLADE THEN YOU TAKE THE BURR OFF THE BLADE!

That's all there is to sharpening. Having said that, if it really is that easy, why does every stylist whose been cutting hair for more than 3 years have a horror story about some sharpener who ruined her shears?

The answer is really two fold.

First a caveat. I really doubt that anyone who wants to be a sharpener really tries to do a bad job, the biggest problem is they (the sharpeners) have believed the wrong people when they purchased their equipment and took their training.

To truly understand how the sharpening industry developed you have to really look at the history of shears.

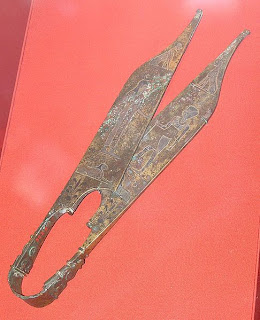

Here's a picture of a very early pair of scissors.

The modern scissors is defined as, "are hand-operated cutting instruments. They consist of a pair of metal blades pivoted so that the sharpened edges slide against each other when the handles (bows) opposite to the pivot are closed."

Pivoted scissors were not manufactured in large numbers until 1761, when Robert Hinchliffe produced the first pair of modern-day scissors made of hardened and polished cast steel.

Since then most scissors are of that same basic design. A straight blade hinged in the middle with a bevel edge. The picture below is a simple barber shear priced at about $30. Modern high quality hair styling shears, price wise, typically start at around $200 and go up into the Thousands.

For the last 250 years sharpening any blade was done using a grinder. Originally a large stone wheel spun manually where the blade (everything from swords to knives and shovels to axes) were all sharpened basically the same way. As power technology became available hooking a grinding wheel up to a motor proved a far more efficient method to spin the grinder wheel that by hand.

Essentially grinders were the only method used for sharpening.

Here's a picture of an old grinder:

And here's a new twin head grinder:

The problem is that most hair cutters (somewhere between 75% and 90% nationwide use what are known as Japanese Style Shears.

These were invented about 50 years ago and have taken the industry by storm. A typical Japanese shear

has a couple of very unique features they are:

- First, the convex edge. This smooth rounded edge gives us the ability to put a much sharper angle on the cutting edge of the blade.

- Second, the 800 MM radius. A slight curve from hilt to tip on the blade. That slight curve is important in that it changes the "angle of attack" so the hair doesn't push away.

Here is the important thing - almost all sharpening equipment will damage with one or the other or both of those design features.

- Grinders will always convert the convex edge to a bevel edge and provide no consistent way to match the 800mm radius.

- Flat hone machines (also known as water hone machines) can allow you to convex the edge but they will consistently flatten the radius.

In both cases no matter how good the sharpener nor how hard he tries, the shears will not cut the way they were designed to after they finish with them.

So if you spent $30 on a pair of barber scissors why bother getting them sharpened. Simply toss them out and buy a new pair. But if you have invested hundreds if not thousands of dollars in high quality shears you'll want to keep them in perfect working order.

But didn't I just say no one can sharpen hair styling shears?

Well there is one and only one alternative that produces an exquisitely sharp blade and still maintains or restores both the convex edge and the 800 MM radius.

The Diamond Rose Shears Superior Sharpening System, the only sharpening equipment in the world capable of maintaining or even restoring shears to factory new condition. This patent protected technology is the only system that can do both.

Don't be fooled even sending your shears "back to the factory" merely gets them to a sharpening service center where they are using, typically, a flat hone machine. Don't be fooled by people saying that the 800mm radius is not important and should not be restored. The reason they say that is they cannot maintain it nor restore it.

So when you take the Diamond Rose Superior Sharpening System and combine it with the intense training course you wind up with the only scissors sharpeners on the planet who can say they literally are the best.

For more information about scissors:

For more information about the sharpening business: